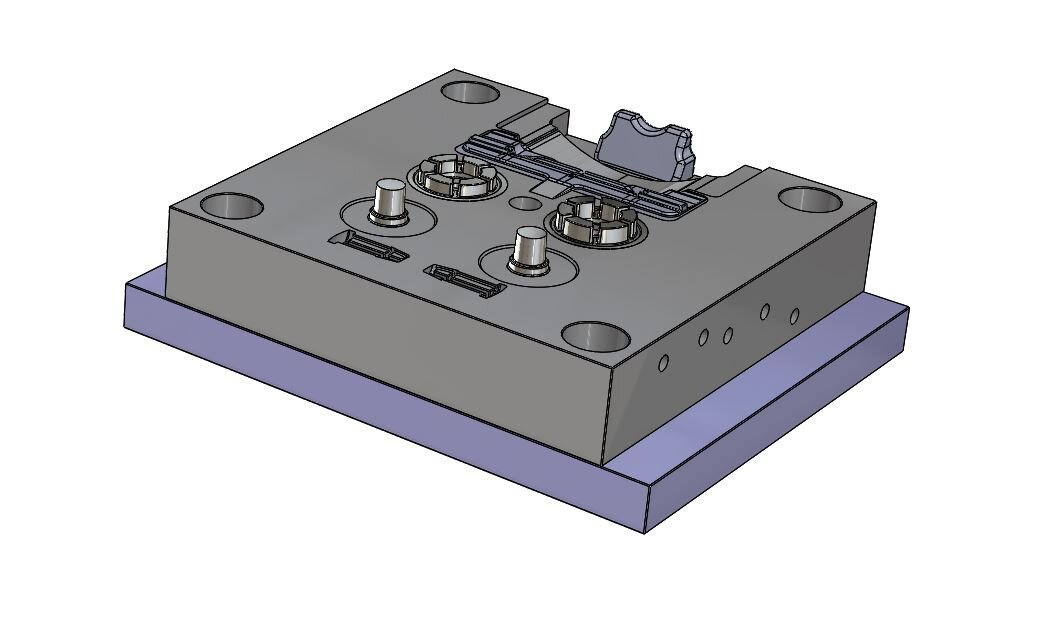

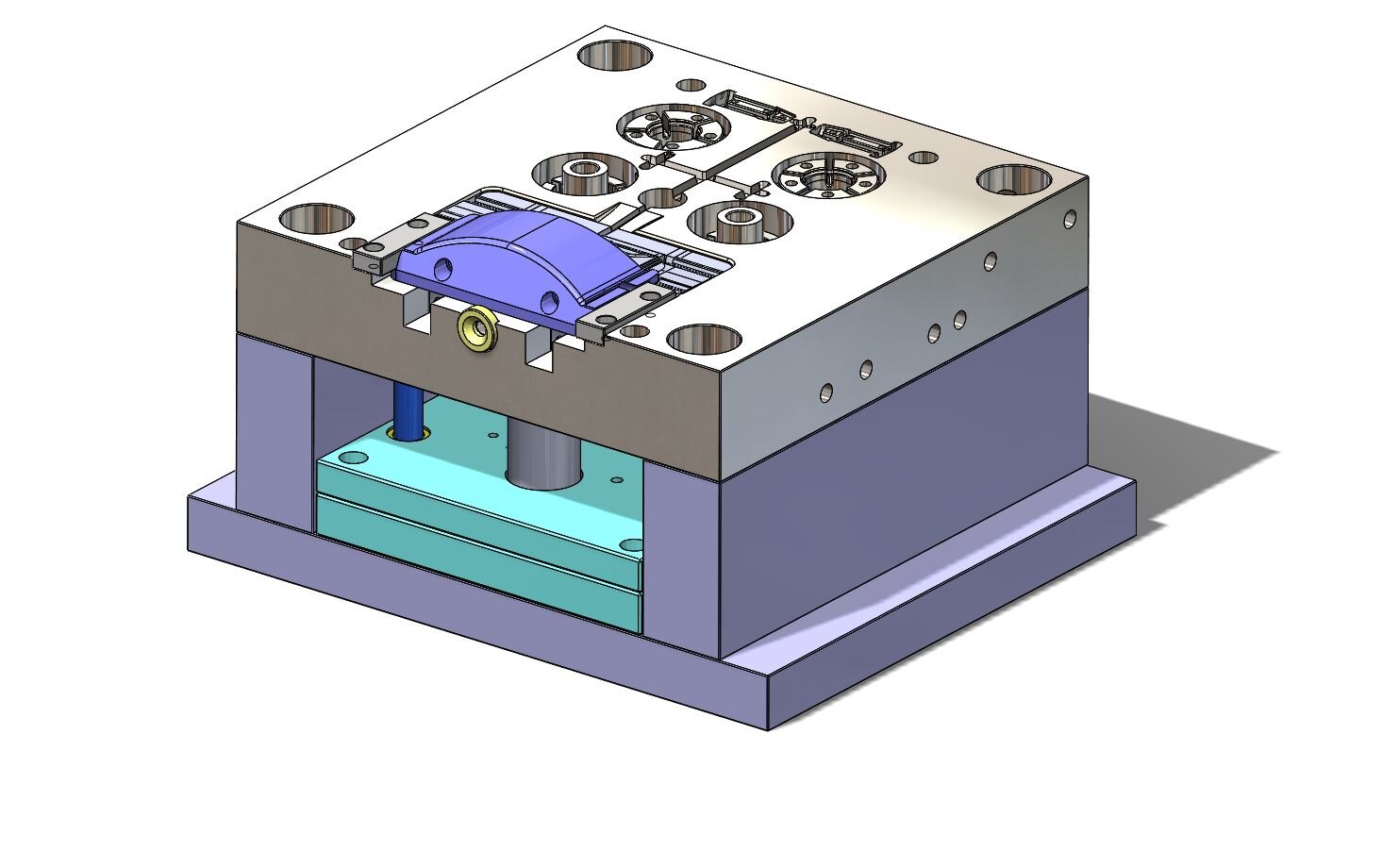

Plastic Injection Tool Design

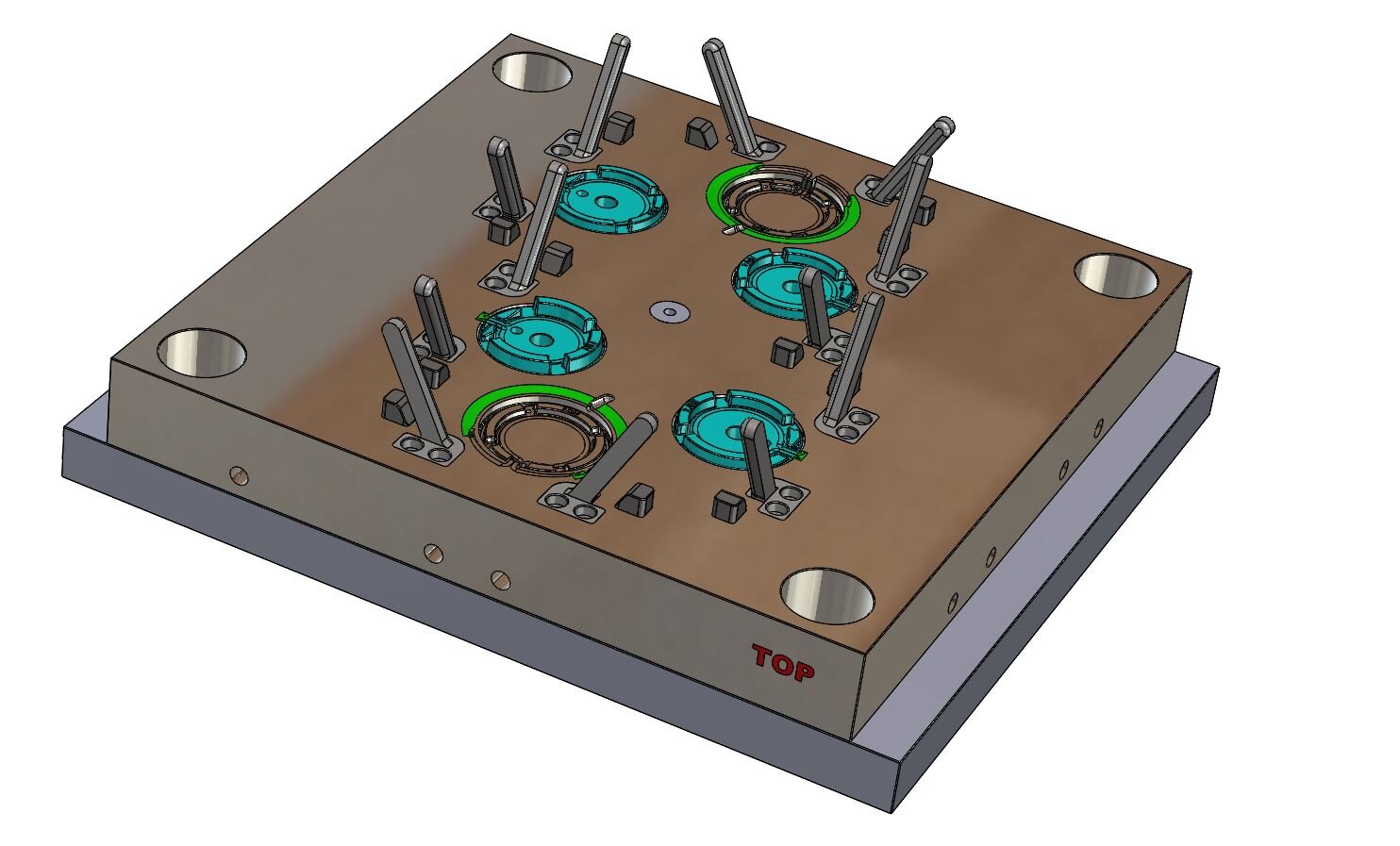

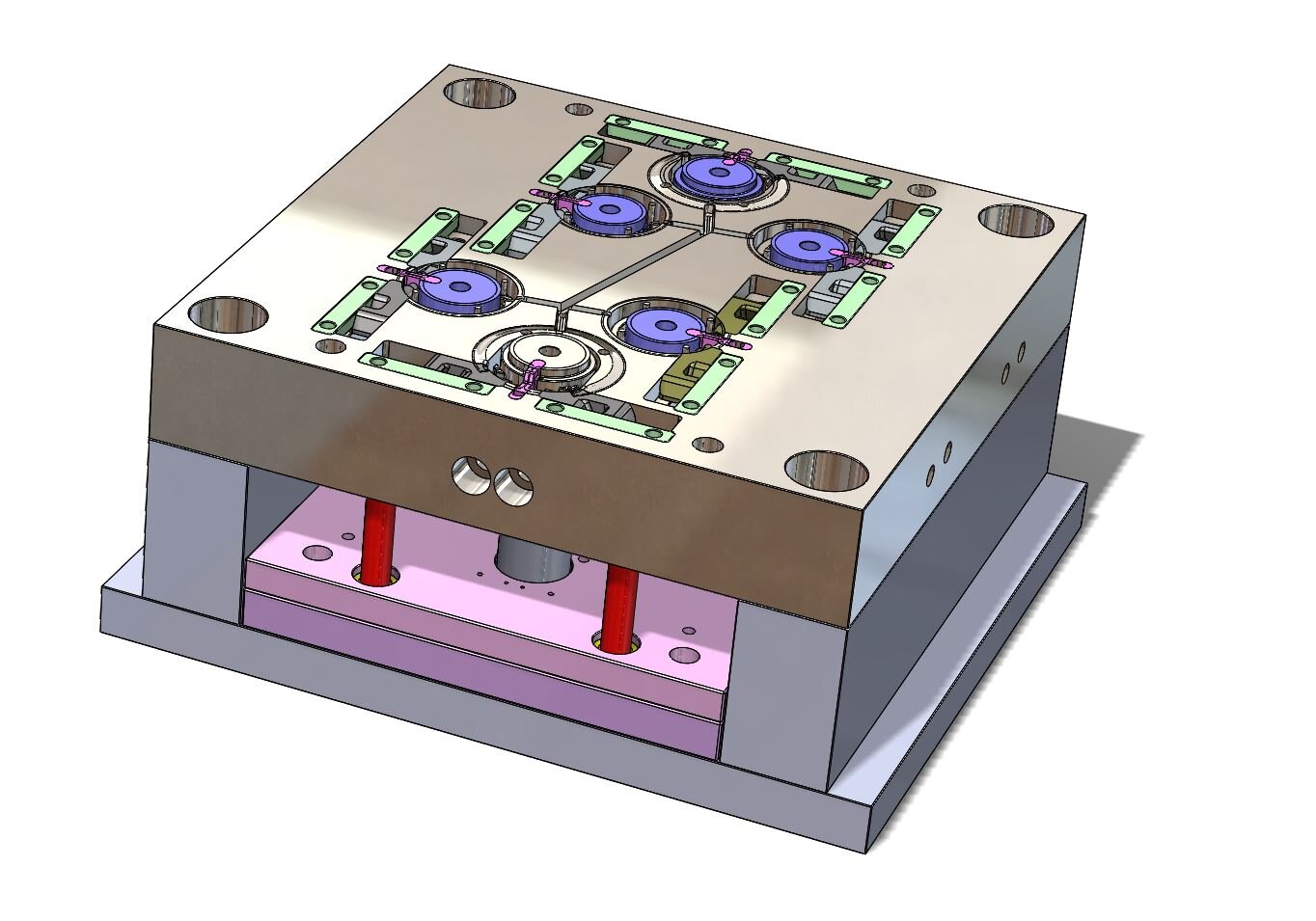

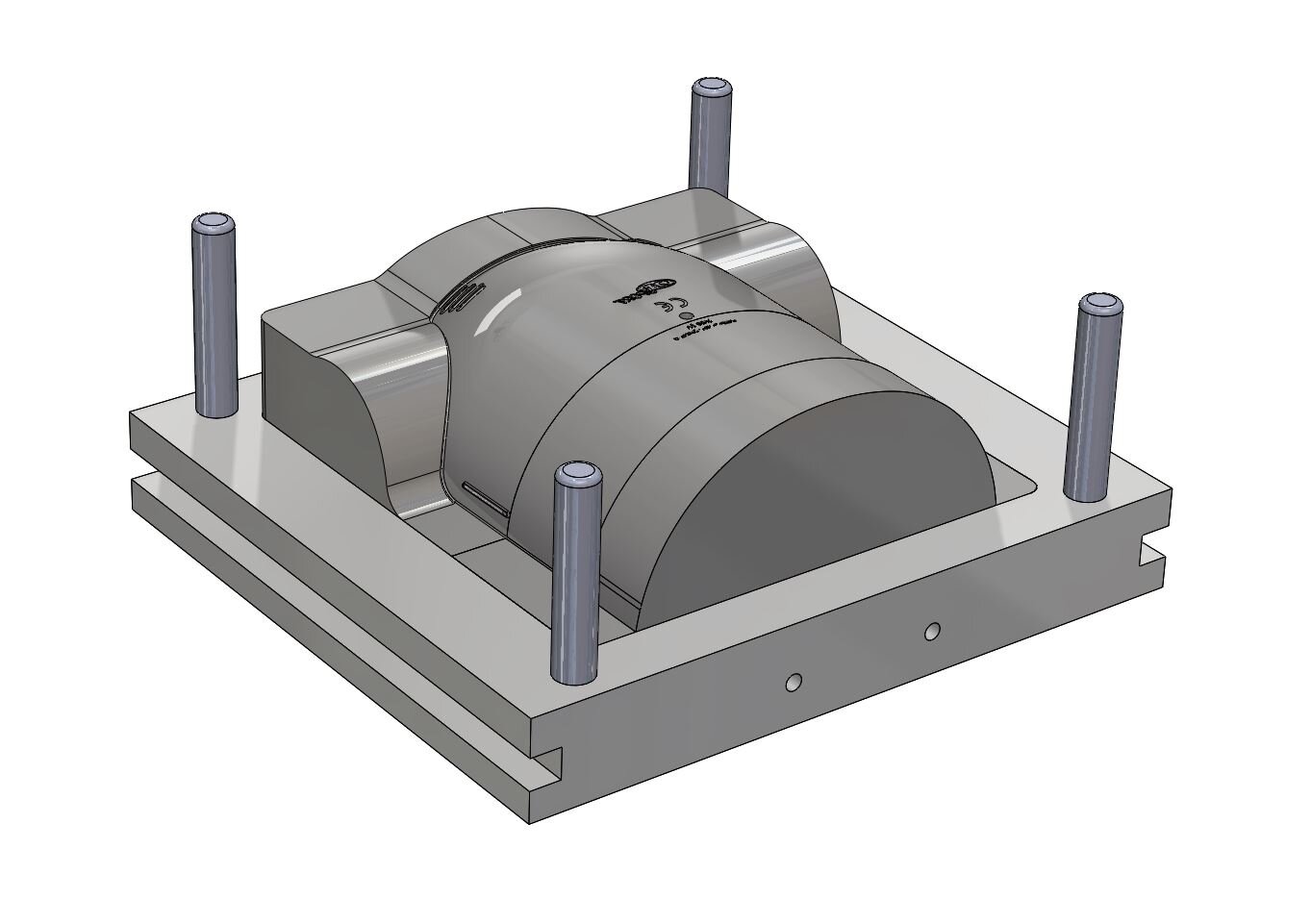

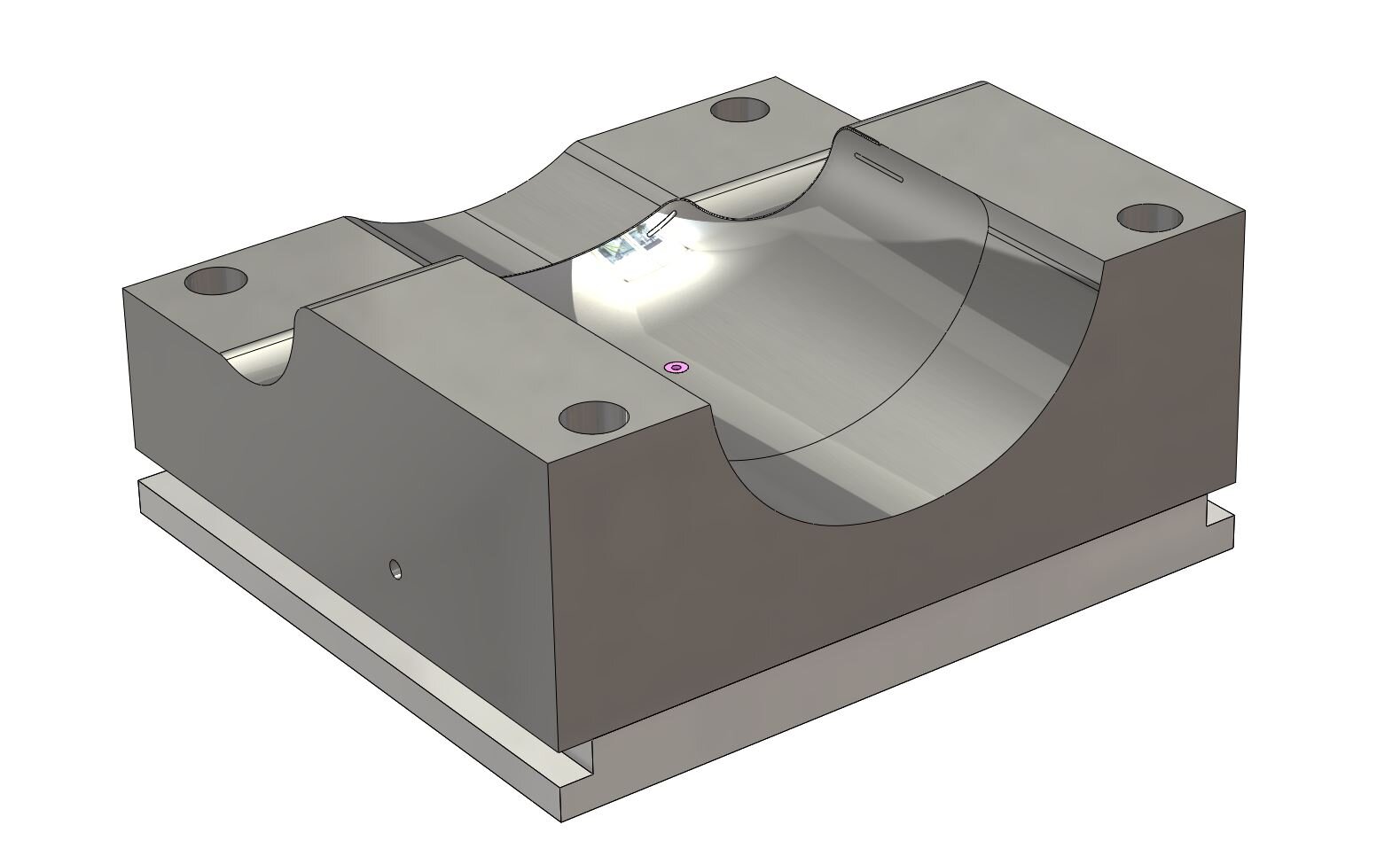

Tool design is planning how to produce mass quantities of a product.This may be in the field of plastic moulding, press stamping, die casting or production automation. This involves a number of steps in relation to the customers needs and we can design a tool that has multiple cavities for large product volume requirements or you can have multiable products designed into one tool. There is low volume product requirements so cheaper tools can be designed.

Streamline Your Production With Help From a Proven Tool Designer

From sheet metal to molten plastic, a huge number of essential components are made by a tool designer. While the form and function of the final element must come first, what comes next is creating the tools that can make those components. Without the appropriate design, achieving the appropriate tolerances and the ability to replicate the part throughout hundreds of thousands of cycles is almost impossible. However, when correctly implemented, you’ll find that your investment can last for years of reliable manufacturing.

At CJ CAD Services, we provide tooling design solutions appropriate for a wide variety of industries. Bringing more than 30 years of understanding in these processes and fielding a team that understands how to leverage modern software solutions fully, we represent a very cost-effective way to design new tools. As a major expense for many businesses, we aim to make tooling design more accessible.

What You Should Know About Plastic Injection Mould Design

One area in which clients often call upon us for help is in the realm of plastic injection moulding. A process used to create an incredible variety of products worldwide, working with thermoplastics could be the perfect solution for those who need durable parts. What should you understand about this design process?

There are many elements to successful mould design beyond faithfully reproducing the part, although that is the clear top priority. Ensuring proper flow through the mould and equal cooling throughout is a critical element of design.

Complete mould design includes pre-production analyses and simulations of real-world moulding conditions with the profile of the materials you intend to use. At CJ CAD, this important element of quality control is an integral part of our work.

Advanced moulding designs, when properly executed, can last for an immense number of cycles, dropping the price per unit dramatically.

The Benefits of Press Tool Design by CJ CAD Services

Alongside injection moulding and blow moulding, we’re adept at designing tools built for pressing and shaping metal. Using the power of hydraulics and gravity, it’s possible to shape even the most rugged materials — but good tool design is essential. When you choose our team, you’ll enjoy advantages such as:

Honesty and transparency throughout the process. We often communicate with our clients to keep you fully engaged and aware of where we’re at in each step.

Competitive pricing and detailed quotes. We’re transparent in our pricing so that our partners can more capably budget for the tooling design they require.

Rigid adherence to deadlines and quoted quality. We take pride in keeping our word. When we make a promise to you for delivery, we always strive to meet or exceed your expectations.

What You Stand to Gain by Choosing CJ CAD Services

With a team that you can count on for quality, it’s simple to remove a large amount of the stress from the tooling stage of your manufacturing process. With reliable outcomes and proven projects that demonstrate our experience, CJ CAD Services is well-positioned to assist you in setting up your business for future successes. Contact our team today to explore your options for local tool design services.